Can Curved Bullet Resistant Vehicle Glass made for any vehicle?

Is Curved Bullet Resistant Vehicle Glass thicker than normal glass?

Is Curved Bullet Resistant Vehicle Glass heavier than normal glass?

Will My Side Door Windows Still Roll Up and Down?

How does thicker Curved Bullet Resistant Vehicle Glass fit in my vehicle?

What about my rear window defroster… will it still work?

Is Curved Bullet Resistant Vehicle Glass expensive?

Why is Curved Bullet Resistant Vehicle Glass expensive?

How is Curved Bullet Resistant Vehicle Glass Manufactured?

James Bond movies and television shows have made “Bulletproof Glass” a household name. It has become a mysterious enigma, so to speak. We will try and dispel the mystery and misinformation about bulletproof glass.

In the real world, “bullet proof” does not exist. When speaking in terms of protection from hand guns and rifles the proper term is bullet resistant, as nothing is truly bulletproof. If given enough time and effort, any bullet resistant product can be defeated.

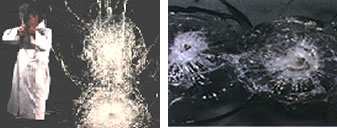

Bullet resistant glass is not at all like it has been portrayed. In movies and TV, bullet resistant glass is portrayed as being no thicker or different from “normal” glass. Bullet resistant glass is often assumed to be “bulletproof,” and it is assumed that it just stops bullets with no regards what is being shot at the glass from a small handgun to rockets. On TV, the bullets just bounce off the glass and away you go! The photo below shows the impact of a bullet into real bullet resistant glass. (Note that the bullets are embedded into the glass)

Bullet resistant glass is manufactured in different protection levels: from level 2, stopping handguns such as .9mm & .357 Magnums at .825″ thick, to our Level 7- Armor Piercing Protection from a .30-06 Rifle at 2.27″ thick. As the level of protection increases, so does the weight, thickness and price.

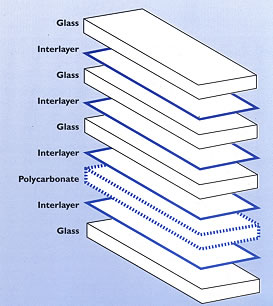

Curved Bullet Resistant Vehicle Glass is a Glass-Clad Polycarbonate multi-ply composite laminate combing polycarbonate and glass using special polyurethane high adhesion bonding interlayers which allow or the expansion/contraction differential of both materials. This special interlayer and the manufacturing process are key elements in controlling the 10:1 thermal expansion ratio. This design allows us significant latitude to almost any ballistic threat from .9mm handguns to .30-06 AP rounds. Combining the the obvious advantages of glass and polycarbonate provides three primary benefits over ALL-Glass composites. #1= Thickness and weight savings up to 60% over conventional ALL-Glass systems. #2= Multiple impact protection and high ballistic protection from rifles. #3= The high structural integrity of polycarbonate with the abrasion, chemical, flame resistance of glass.

Polycarbonate is plastic material thirty times stronger than acrylic, which is seventeen times stronger than an equal thickness of single strength glass. Polycarbonate, therefore, is an excellent impact barrier and is used as the core material of our bullet resistant composite. Polycarbonate is susceptible to abrasion, scratching, chemical attack, heat and flame. Polycarbonate alone is not an effective ballistics barrier above handgun protection. Our solution is a combination of these materials to take advantage of their benefits while eliminating their individual shortcomings.

All of our protective glass systems are directly interchangeable with OEM (Original Equipment Manufacturer) glass. Our Curved Bullet Resistant Vehicle Glass meets standards set by: [ANSI] American National Standards Institute, [SAE] the Society of Automotive Engineers [DOT] Department of Transportation, and [ASTM] American Standard Testing Materials. Ballistic testing provided by: H.P. White Laboratories Inc.

Question: Can Curved Bullet Resistant Vehicle Glass made for any vehicle?

Answer: Curved Bullet Resistant Vehicle Glass can be custom manufactured for most vehicles. However, some vehicles are not well suited for Bullet Resistant Vehicle Glass, vehicles such as Chevrolet Camaro and Corvette, Dodge Viper, Pontiac Trans-Am, and other such vehicles. Vehicles with no upper door frame and convertible top vehicles are NOT good choices for Curved Bullet Resistant Vehicle Glass.

Question: Is Curved Bullet Resistant Vehicle Glass thicker than normal glass?

Answer: Standard Auto Glass is 5/32″ thick. Unlike in Bond movies and television shows, real Curved Bullet Resistant Vehicle Glass is anywhere from .825″ to 2.27″ thick.

Question: Is Curved Bullet Resistant Vehicle Glass heavier than normal glass?

Answer: The standard auto glass in your vehicle weighs approx. 3.5 lbs per sq.ft. Real Curved Bullet Resistant Vehicle Glass weight is anywhere from 8.98 lbs.per sq. ft. to 26.71 lbs. per sq. ft.

Question: Will My Side Door Windows Still Roll Up and Down?

Answer: Curved Bullet Resistant Vehicle Glass does not work very well in the rolled down position! All kidding aside, installing a set of Curved Bullet Resistant Vehicle Glass in your vehicle is a very serious consideration. Our Curved Bullet Resistant Vehicle Glass is designed to save your life from handguns and rifles. Operable side door vehicle glass is not very common in vehicle armoring.

Standard auto glass is 5/32″ thick. Most modern vehicle doors now have side air bags, side impact braces, etc. There is usually not much room left for thicker bullet resistant glass to fit inside the door without some modification to the door and trim. In most cases you can expect to get from 4″-7″ of roll down, depending on your type of vehicle and level of protection needed.

Question: How does thicker Curved Bullet Resistant Vehicle Glass fit in my vehicle?

Answer: Curved Bullet Resistant Vehicle Door Glass is manufactured with glass offsets. If you look at the photo (above left) of the open drivers door, you will notice a partly rolled down bullet resistant window. You will notice that we have left an apron 1″ of glass that is just a little thicker than the glass in your current vehicle, or “offset”. These “offsets” are at the top and sides of the door, thus allowing our thicker glass to fit inside your vehicles door frame. With the Bullet Resistant window rolled all the way up, or permanently installed, the glass rests against the rubber window trim, with the addition of a black paint band around the glass as the above photo shows. We are able to hide this offset from showing. This also optically hides the thickness of the glass from view, making your vehicle look stock.

Curved bullet resistant vehicle windshields and back lights are manufactured in much the same way as side door glass. That thick black paint border on most vehicles is there for one reason: to hide where the glass is glued to your vehicle and where the inside trim meets the glass. If the windshield were removed from your vehicle, you would notice that there is an “offset” in the metal on the roof and spiller posts. This “offset” is approx. 1-2″ wide and the thickness of your vehicles OEM Glass. These “offsets” are at the top and sides of the windshield. The back light and rear window also has an “offset” of approx. 1-2″ wide plus the thickness of your vehicle’s OEM glass around all sides. We manufacture an apron 1″ of glass that is just a little thicker than the glass in your current vehicle or “offset”. These “offsets” allow our thicker glass to fit inside your vehicles windshield and rear window frames. Again, with the addition of a black paint banding around the glass, we are able to hide this offset from showing. This also optically hides the thickness of glass from view, making your vehicle look stock.

Question: What about my rear window defroster… will it still work?

Answer: We can manufacture Curved Bullet Resistant rear windows using the existing glass, along with with our glass and polycarbonate, or we can add heat strips to the unit in our manufacturing process.

Question: Is Curved Bullet Resistant Vehicle Glass expensive?

Answer: You would be surprised at the replacement cost for your vehicles OEM (Original Equipment Manufacturer) Glass. OEM glass for your vehicle could be from around $2,500.00 to over $6,000.00 in price for a Ford Expedition. Pricing for Curved Bullet Resistant Vehicle Glass can start from around $7,000.00 to well over $20,000.00, depending on your type of vehicle and level of protection needed.

Question: Why is Curved Bullet Resistant Vehicle Glass expensive?

Answer: Fair question… most individuals have never been in the market for Curved Bullet Resistant Vehicle Glass and have nothing to base a price quotation on, other than what they feel the price should be. An informed consumer is always in a better position to make a decision with the proper knowledge and information.

The custom manufacture of Curved Bullet Resistant Vehicle Glass is part art, part science, and requires the proper equipment and technical expertise. Curved Bullet Resistant Vehicle Glass can cost anywhere from $6,000.00 for a pick up truck to $18,000.00 for a large SUV.

Vehicle Glass Molds: The custom manufacture of Curved Bullet Resistant Vehicle Glass starts with us making a set of molds of your vehicle’s OEM glass. The molds are an exact copy of the glass in your vehicle. This gives us all of the curvature and bends that your vehicle’s glass has. These molds will be later used in the bending process explained below.

Layout and Cutting: The next step in manufacturing process is to cut all of the needed door and window units from flat sheet glass stock, along with the sheets of polycarbonate and polyurethane bonding interlayers. The first layer of of glass is cut to the exact size of your vehicle’s OEM glass. The next layer is the first of several of polyurethane bonding interlayers. The next set of glass is cut to the “offsets” as described above. The final “lay-up” can be from 2-5 units of glass and 1-2 layers of Polycarbonate. The inside of your new Curved Bullet Resistant Vehicle Glass can be manufactured for you in two ways: Low Spall: (Glass on the inside of the vehicle) and No-Spall: (Polycarbonate on the inside of the vehicle).

Glass Bending: The next step in manufacturing process is the “bending” oven. Here, the molds come into play. We take the cut flat glass and polycarbonate units as described above, and set them on the molds in the bending oven. Bending ovens look almost like giant pizza ovens. The “lay-up” heats up slowly over eight hours to a certain temperature and then slowly slumps the glass to the exact size and dimensions of the mold. The bent glass must slowly cool down again over about 8 hours before it can be safely removed from the bending oven. At this point, the glass is very fragile any quick temperature change during the cool down process will cause the unit to break or crack, at which point the process must be started over.

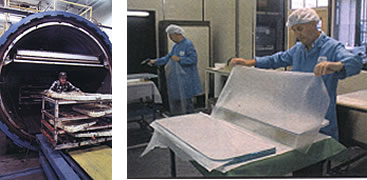

Clean Room Assembly: Once the “lay-up” has cooled down properly and has been removed from the bending oven, all the individual units are completely cleaned. We now take the cleaned “lay-up” to our cleanroom for final assembly. There, all the bent glass and the layers of polyurethane bonding inter-layers are assembled in the proper configuration. Then, we thoroughly inspect the final assembly for proper size, and for defects in the manufacturing process. Our General Manager, Shop Foreman, and Production Manager must all check off on the final assembly before it is sent to the autoclave for final bonding of the unit.

Vacuum Bag Assembly: After passing our very stringent inspection, the full “lay-up” is then inserted into a vacuum bag and sealed. We then pull a vacuum on the bag, removing all of the air.

Autoclaving: The final step in manufacture is loading the vacuum bagged assembly in to one of our two large autoclaves. (These are just a slightly larger version of what your local dentist uses to sterilize their instruments.) The heat and pressure of the autoclave bonds all of layers of polyurethane, glass, and bonding interlayers together. The autoclave cycle takes 12 hours to bond the vacuum bagged assembly in to the finished product. It also takes about 8 hours for proper cooldown time.

Final Inspection & Boxing: After the finished Curved Bullet Resistant Glass has been removed from the autoclave, it is rechecked against the molds and OEM glass to make sure the new glass has a proper fit and appearance. Again our General Manager, Shop Foreman, and Production Manager must all check off on the final assembly before it is boxed for shipment to you.

Tested By: H.P. White Laboratories Inc.